CloseIt Bag Closures: Choosing the Right Clip Size

Plastic “tab-style” bag closures are a popular bag closure type in the produce and bakery industries for securely closing bags while maintaining product freshness. Some of the advantages over other closing methods include:

- Metal-free design – ideal for applications where metal detection is necessary.

- Ability to print date and lot codes on the closure

- Reliable performance in wet or humid conditions – because they’re metal free, plastic clips won’t rust or degrade when exposed to moisture.

Simple as they may seem, choosing the right size is crucial for both performance and appearance. Selecting the wrong size could lead to ineffective closing, difficulty in application, or reduced product shelf life.

How do you determine the best closure size for your needs? Consider the following key factors.

1. Product in your bag

The thickness of the clip plays an important role in the overall functionality of your packaging. Thicker clips provide added durability, which is especially important for heavier products.

Bedford’s CloseIt Clips, for instance, are available in two standard thicknesses:

- .030-inch thickness – best suited for lightweight products (under 5 pounds), commonly used for baked goods and snacks.

- .045-inch thickness – Recommended for heavier bags (over 5 pounds), such as bulk produce.

By selecting the appropriate thickness, you can ensure that your clip maintains a secure closure without compromising ease of use.

2. Bag type & dimensions

The shape of the closure’s opening is another important factor. This determines how snugly the clip fits around the bag when it’s bunched together. A clip that is too loose may not hold properly, while one that is too tight may be difficult to apply.

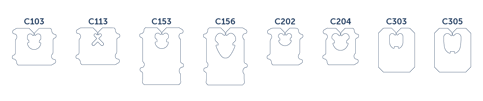

With nearly 20 different closure shapes in the CloseIt line, Bedford ensures the best fit for different bag types, considering factors such as:

- Material type – plastic and mesh compatible.

- Bag thickness – thin films may require a different clip shape than thicker, reinforced bags.

- Lay-flat width – the bag’s total width when unfilled affects how it will bunch under the clip.

All CloseIt Clip shapes are also available in Bio-Clip, an industrial compostable option made from 100% USDA biobased content.

3. Printing Options

If you plan to add date codes, lot numbers, or branding to your closure, the length of the clip is an important consideration. Bedford offers:

- Short clips (.8438 inches) – A compact design for simple closures with no or simple printing.

- Long clips (1.3125 inches) – More space for branding information, ideal for tracking expiration dates, batch numbers, and promotional messages.

Clips can be pre-printed at Bedford or printed on-site by integrating a printer with your application equipment. A combination of both is also possible for flexible printing needs.

4. How you’ll apply your bag closure

4. How you’ll apply your bag closure

How your closures are applied affects which clip size will work best. Certain clip shapes are specifically designed for use with automatic or semi-automatic bag closing machines.

- The V1 and H1 bag closers are compatible with our C100 and C150 series

- The M1 semi-automatic closer is compatible with our C300 series.

Order spare parts online.

The Bedford Experience

You don’t have to navigate finding the right size closure on your own. If you have a new product or are placing an order with us for the first time, we’ll send you a project checklist to determine the best closure for your needs.

For machine compatibility, our engineers offer testing services using your bags to ensure the best fit and application–part of The Bedford Experience. Contact us today to get started!

As an added bonus, CloseIt spools have 30% more closures than competitors!